Our technology is based on oxygen-dependent phosphorescence of organic molecules.

Phosphorescence occurs when materials continue to shine after they were previously irradiated with light.

A well-known example is the glowing star you may find on children's bedroom ceilings. This afterglow can last from a few seconds to several hours.

For PRUUVE, the duration is only 0.1 seconds. This often leads to confusion: physically, it is phosphorescence, but it is only visible to the naked eye during UV irradiation due to the brief afterglow.

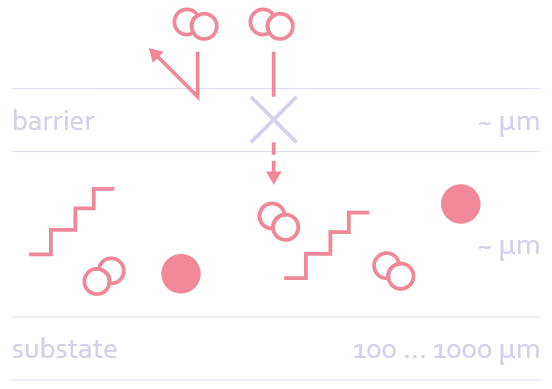

Phosphorescence cannot occur when free oxygen (O₂) is in the vicinity of our emitter molecules. Free oxygen is, however, already in the layer system due to the manufacturing process.

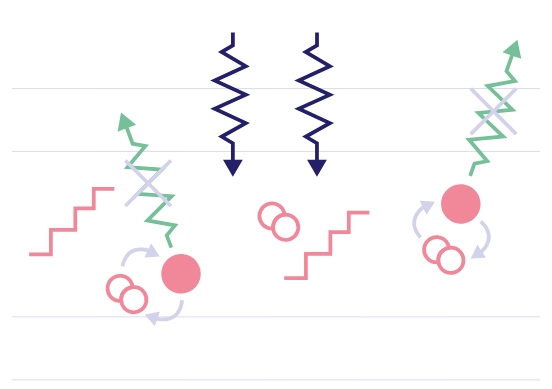

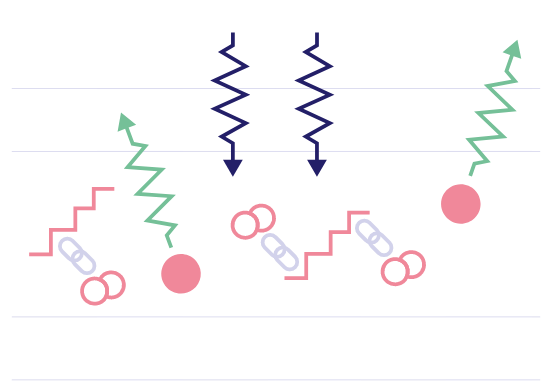

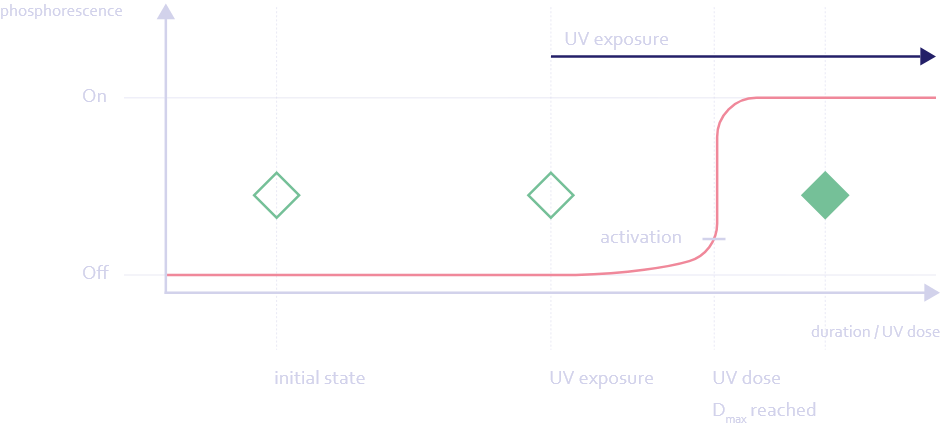

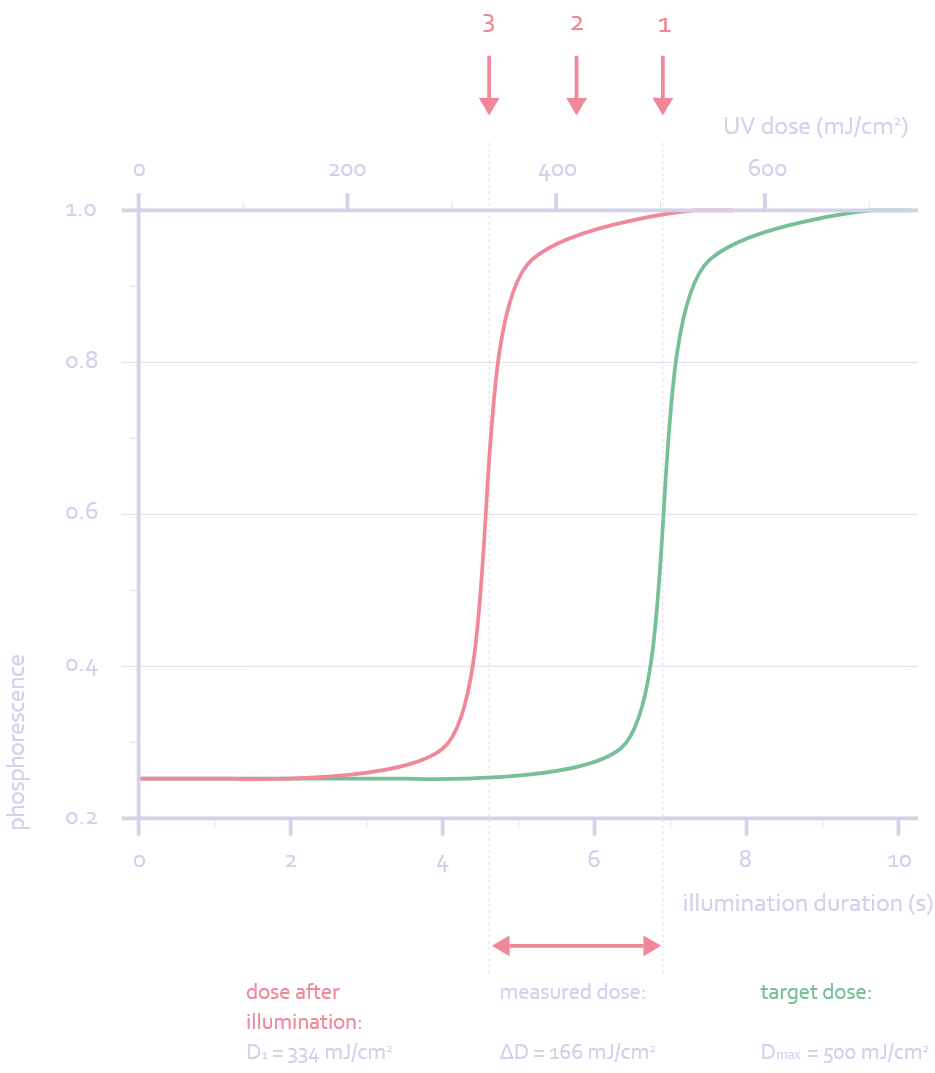

Under UV illumination, the energy is transferred to the oxygen instead of the emitter molecules. The oxygen becomes reactive and binds to the polymer environment. Under continuous UV illumination, the oxygen gradually disappears. Only when the oxygen is completely removed will the phosphorescence appear.

The time until the phosphorescence appears we refer to as the "activation time". This activation time is used as a measure of the radiated UV dose and allows precise UV dose measurements. We can flexibly tune the activation time through recipe adjustments to meet all industrial requirements.

The measuring device irradiates the strips with UV light and measures the time until the phosphorescence appears. Based on the calibration measurement and the measurement after UV exposure, the UV dose is calculated and displayed for the customer.